Description

If the stroke is extended, the control angles are also extended. This means that the scavenging channels in the cylinder (overflow and exhaust channel) are open longer. On the one hand this is very good to generate more power, but on the other hand it can also backfire if the head angles are no longer within a reasonable range or if the remaining components no longer support the achievable speed.

The head angles change most if the additional stroke is compensated at the cylinder base. With a stroke increase from 52mm to 55mm, i.e. 3mm, 1.5mm would have to be underlaid at the foot OR head here. So no 3mm compensation seal is used but only 1,5mm because the piston moves 1,5mm up AND down.

Now 1,5mm is underlaid at the base, due to the angle function of the crank drive, the overflow time increases disproportionately to the exhaust angle. Both angles, overflow and outlet angle, should however always be in proportion to each other for a well-functioning flush. The outlet channel should always open for a certain time before the overflow channels to give the old gases enough time to escape and make room for the incoming fresh gas. If the function of this process, known as the pre-exhaust angle, is disturbed by a too high overflow angle (or an exhaust angle that is too short in relation to the overflow angle), the power delivery in the upper speed range will be massively disturbed. Then the best exhaust system simply doesn't work anymore because it lacks the surface to breathe. If the exhaust is a real racing exhaust that only makes music in the upper speed range, this is usually accompanied by a pronounced lack of power in the lower speed range. So the engine would be slower than an original engine, despite more stroke and expensive exhaust, because the exhaust steals the torque from the bottom and the cylinder cannot deliver it from the top. The smaller the angle, the less purge loss the cylinder has, but also correspondingly less power in the upper rpm range. On the other hand, a large pre-exhaust angle is perfect to support high performance exhaust systems, but carries the risk of losing a lot of power in the lower speed range.

For the beginning it is therefore usually more recommendable to compensate the extra stroke at the cylinder head to avoid too high a change of the head angle.

If a compensation at the cylinder base is desired, which is usually easier to realize with water-cooled engines, the exhaust angle often has to be adjusted mechanically, i.e. the exhaust must be milled to achieve the desired forward exhaust angle.

However, depending on the cylinder type, this requires skill, tools and know-how.

Calibrating the control angle is just as essential as the subsequent adjustment of the ignition angle and carburetor spraying.

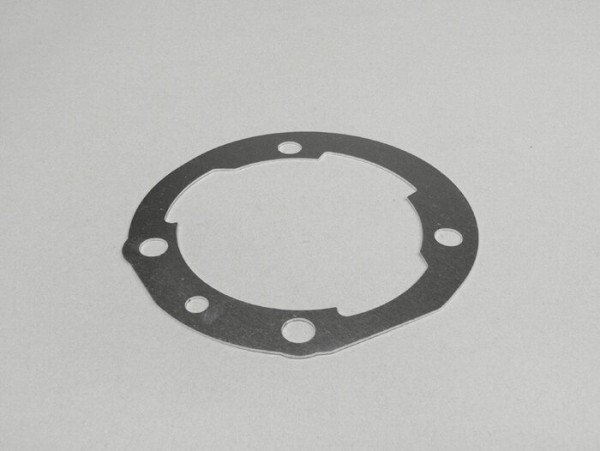

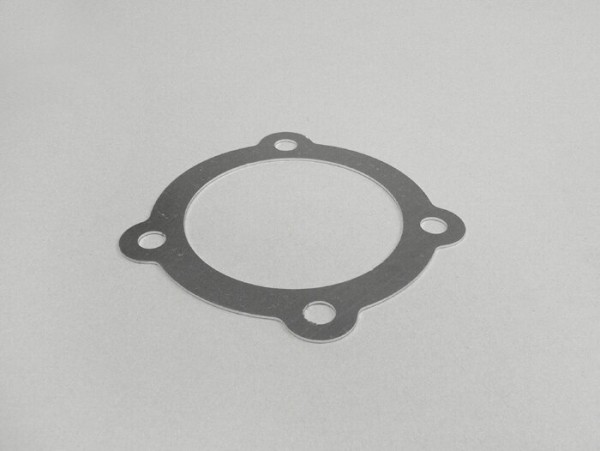

cylinder head gasket -BGM PRO- 1.0mm Malossi 210ccm (aluminium)

AI-translation

+----------+

Manufacturer Information

bgm

Kurt-Schumacher-Straße 1

50129 Bergheim - Germany

https://www.scooter-center.com/

info@scooter-center.com

Responsible Person for the EU

Scooter Center GmbH

Kurt-Schumacher-Str. 1

50129 Bergheim-Glessen - Germany

https://www.scooter-center.com/

info@scooter-center.com

incl. VAT plus shipping costs

| Spacers | |

|---|---|

| spacer used for component: | cylinder/cylinder head |

| material: | aluminium |

| thickness: | 1 mm |

| Customers alternatively searched for | |

|---|---|

| Spacer | Zylinderkopf | Distanzdichtung | Distanz | Zylinderspacer | Kopfspacer | Fußspacer | Cylinder | Head | Gasket | Thick | Cale De Culasse | Spacer Testata | Spacer Culata | | |

Available versions

Fits the following vehicles

- Vespa (Piaggio) Vespa 200 Rally (VSE1T, Femsa)

- Vespa (Piaggio) Vespa 200 Rally (VSE1T, Ducati)

- Vespa (Piaggio) Cosa 200 CL (VSR1T)

- Vespa (Piaggio) Cosa 200 CLX (VSR1T300)

- Vespa (Piaggio) Cosa 200 FL (VSR1T301)

- Vespa (Piaggio) P 200 E (VSX1T, -1980)

- Vespa (Piaggio) PX 200 E FL (VSX1T, 1984-1997)

- Vespa (Piaggio) PX 200 E (VSX1T, 1981-1983)

- Vespa (Piaggio) PX 200 E FL (ZAPM18, 1998-)